Lista de productos

- Sistema Anchorge

- Filamento de acero galvanizado en caliente

- Alambre de acero galvanizado en caliente

- Filamento pretensado

- Filamento de acero pretensado con recubrimiento epóxico de siete alambres

- Filamento de acero pretensado de alta resistencia a la tracción galvanizado en caliente

- Filamento de acero de hormigón pretensado de baja relajación

- Filamento de acero pretensado de unión lenta

- Filamento de acero pretensado sin unión

- Barras pretensadas de acero de hormigón

- Alambre pretensado

- Filamento de acero recubierto (Galfan) de Zinc-5%

- Alambre de acero recubierto de Zinc-5%

| Home -> Filamento de acero galvanizado en caliente |

Productos

Filamento de acero galvanizado en caliente

Aplicación: Alambre de núcleo de acero para ACSR, cable de energía, conductores aéreos, alambre aéreo de tierra, cable de telecomunicaciones, cable mensajero, cable de tierra, alambre de estancia, alambre de retención, valla, etc.

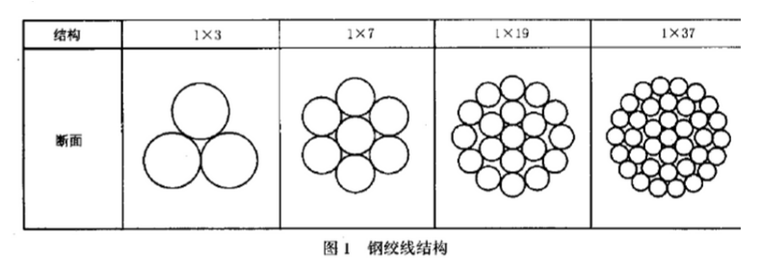

Estructura y diámetro:

1x3, Dia 6.20~8.6mm

1x7, Dia 3.0~12.0mm

1x19, Dia 8.0~20.0mm

1x37, Dia 11.2~28.0mm

Estándar: YB/T5004-2001,ASTM A475,ASTM A363,BS183.

Especificación especial y requisito pueden ser ordenados.

Embalaje: tiras agrupadas de acero y láminas de plástico envueltas en el exterior o por el carrete de madera.

Estructura y diámetro:

1x3, Dia 6.20~8.6mm

1x7, Dia 3.0~12.0mm

1x19, Dia 8.0~20.0mm

1x37, Dia 11.2~28.0mm

Estándar: YB/T5004-2001,ASTM A475,ASTM A363,BS183.

Especificación especial y requisito pueden ser ordenados.

Embalaje: tiras agrupadas de acero y láminas de plástico envueltas en el exterior o por el carrete de madera.

|

|

|

| Standard | Structure |

Nominal

diameter

of steel

strand

|

Nominal diameter of coated wire in strand | Tolerance of nominal diameter of steel wire | Cross Sectional Area | Tensile Strength Grade of strand (Mpa) | Theoretical Weight per meter | ||||

| 1270 | 1370 | 1470 | 1570 | 1670 | |||||||

| mm | mm | mm | mm2 | Breaking Load of strand (KN)≥ | g/m | ||||||

| YB/T5004-2001 | 1 x 3 | 6.2 | 2.90 | ±0.08 | 19.82 | 23.16 | 24.98 | 26.8 | 28.63 | 30.45 | 160 |

| 6.4 | 3.20 | 24.13 | 28.19 | 30.41 | 32.63 | 34.85 | 37.07 | 195 | |||

| 7.5 | 3.50 | ±0.10 | 28.86 | 33.72 | 36.38 | 39.03 | 41.69 | 44.34 | 233 | ||

| 8.6 | 4.00 | 37.7 | 44.05 | 47.52 | 50.99 | 54.45 | 57.92 | 304 | |||

| 1 x 7 | 3 | 1.00 | ±0.05 | 5.5 | 6.43 | 6.93 | 7.44 | 7.94 | 8.45 | 43.7 | |

| 3.6 | 1.20 | 7.92 | 9.25 | 9.98 | 10.71 | 11.44 | 12.17 | 62.9 | |||

| 4.2 | 1.40 | 10.78 | 12.6 | 13.59 | 14.58 | 15.57 | 16.56 | 85.6 | |||

| 4.8 | 1.60 | 14.07 | 16.44 | 17.73 | 19.03 | 20.32 | 21.62 | 112 | |||

| 5.4 | 1.80 | ±0.06 | 17.81 | 20.81 | 22.45 | 24.09 | 25.72 | 27.36 | 141 | ||

| 6 | 2.00 | 21.99 | 25.69 | 27.72 | 29.74 | 31.76 | 33.79 | 175 | |||

| 6.6 | 2.20 | 26.61 | 31.1 | 33.55 | 36 | 38.45 | 40.88 | 210 | |||

| 7.8 | 2.60 | ±0.08 | 37.17 | 43.43 | 46.85 | 50.27 | 53.69 | 57.11 | 295 | ||

| 9 | 3.00 | 49.5 | 57.86 | 62.42 | 66.98 | 71.54 | 76.05 | 411.9 | |||

| 9.6 | 3.20 | 56.3 | 65.78 | 70.96 | 76.14 | 81.32 | 86.5 | 447 | |||

| 10.5 | 3.50 | ±0.10 | 67.35 | 78.69 | 84.89 | 91.08 | 97.28 | 103.48 | 535 | ||

| 11.4 | 3.80 | 79.39 | 92.76 | 100.1 | 107.4 | 114.7 | 121.97 | 630 | |||

| 12 | 4.00 | 87.96 | 102.8 | 110.9 | 119 | 127 | 135.14 | 698 | |||

| 1 x 19 | 8 | 1.60 | ±0.05 | 38.2 | 43.66 | 47.1 | 50.54 | 53.98 | 57.41 | 304 | |

| 9 | 1.80 | ±0.06 | 48.35 | 55.26 | 59.62 | 63.97 | 68.32 | 72.67 | 385 | ||

| 10 | 2.00 | 59.69 | 68.23 | 73.6 | 78.97 | 84.34 | 89.71 | 475 | |||

| 11 | 2.20 | 72.2 | 82.58 | 89 | 95.58 | 102.1 | 108.52 | 569 | |||

| 11.5 | 2.30 | 78.94 | 90.23 | 97.33 | 104.4 | 111.5 | 118.65 | 628 | |||

| 13 | 2.60 | ±0.08 | 100.9 | 115.3 | 124.4 | 133.5 | 142.6 | 151.65 | 803 | ||

| 14.5 | 2.90 | 125.5 | 143.4 | 154.7 | 166 | 177.3 | 188.63 | 999 | |||

| 16 | 3.20 | 152.8 | 174.7 | 188.4 | 202.2 | 215.9 | 229.66 | 1220 | |||

| 17.5 | 3.50 | ±0.10 | 182.8 | 208.9 | 225.4 | 241.8 | 258.3 | 274.75 | 1460 | ||

| 20 | 4.00 | 238.8 | 272.9 | 294.4 | 315.9 | 337.4 | 358.92 | 1900 | |||

| 1 x 37 | 11.2 | 1.60 | ±0.05 | 74.39 | 80.3 | 86.63 | 92.95 | 99.27 | 105.6 | 595 | |

| 12.6 | 1.80 | ±0.06 | 94.15 | 101.6 | 109.6 | 117.6 | 125.6 | 133.65 | 753 | ||

| 14 | 2.00 | 116.2 | 125.4 | 135.3 | 145.2 | 155.1 | 164.95 | 930 | |||

| 16.1 | 2.30 | 153.7 | 165.9 | 179 | 192 | 205.1 | 218.18 | 1230 | |||

| 18.2 | 2.60 | ±0.08 | 196.4 | 212 | 228.7 | 245.4 | 262.1 | 278.79 | 1570 | ||

| 20.3 | 2.90 | 244.4 | 263.8 | 284.6 | 305.4 | 326.2 | 346.93 | 1950 | |||

| 22.4 | 3.20 | 297.6 | 321.3 | 346.6 | 371.9 | 397.1 | 422.44 | 2380 | |||

| 24.5 | 3.50 | ±0.10 | 356 | 384.3 | 414.6 | 444.8 | 475.1 | 505.34 | 2050 | ||

| 28 | 4.00 | 465 | 502 | 541.5 | 581 | 620.5 | 660.07 | 3720 | |||

| Nominal diameter of steel wire used for steel strand | Tolerance of nominal diameter of steel wire | Elongation % | Twist Number of times/360° ≥ | Coating Weight of wire ≥ | Adhesion of Coating | |||||||

| Tensile Strength Grade (Mpa) | g/m2 | Diameter of mandril | Circles | |||||||||

| mm | mm | ≥ | 1270 | 1370 | 1470 | 1570 | 1670 | Super A | A | B | 12d | 6 |

| 1 | ±0.05 | 2.0 | 18 | 16 | 16 | 14 | 14 | 180 | 160 | 110 | ||

| 1.1 | ||||||||||||

| 1.2 | ||||||||||||

| 1.3 | 200 | |||||||||||

| 1.4 | 130 | |||||||||||

| 1.5 | ||||||||||||

| 1.6 | 180 | |||||||||||

| 1.7 | 220 | |||||||||||

| 1.8 | ±0.06 | 3.0 | 16 | 14 | 14 | 12 | 12 | 160 | ||||

| 2 | 230 | 200 | 14d | |||||||||

| 2.2 | 180 | |||||||||||

| 2.4 | 240 | 220 | 200 | |||||||||

| 2.6 | ±0.08 | 250 | ||||||||||

| 2.8 | 14 | 12 | 12 | 10 | 10 | 270 | 250 | 230 | ||||

| 3 | 4.0 | |||||||||||

| 3.2 | 280 | 260 | ||||||||||

| 3.5 | ±0.10 | 290 | 270 | 250 | ||||||||

| 3.8 | ||||||||||||

| 4 | ||||||||||||

Zinc Coating

| Nominal diameter of coated wire in strand | Coating weight | |

| mm | g/m2 | |

| Class A | Class B | |

| 1.60~1.90 | 210 | 420 |

| >1.90~2.30 | 220 | 440 |

| >2.30~2.70 | 230 | 460 |

| >2.70~3.10 | 240 | 480 |

| >3.10~3.50 | 260 | 520 |

| >3.50~3.90 | 270 | 540 |

| >3.90~4.50 | 275 | 550 |

| >4.50~4.80 | 300 | 600 |

| Chemical Composition | % | |

| C | 0.40~0.85 | |

| Si | 0.10~0.35 | |

| Mn | 0.50~1.10 | |

| S | ≤0.045 | |

| P | ≤0.035 | |